In the manufacturing of electronic components—particularly moisture-sensitive devices such as IC chips and semiconductor components—environmental humidity control is critical during production, storage, and transportation. Thanks to its excellent moisture adsorption capacity, chemical stability, and regenerability, activated alumina has become one of the key materials for moisture protection in the electronics industry.

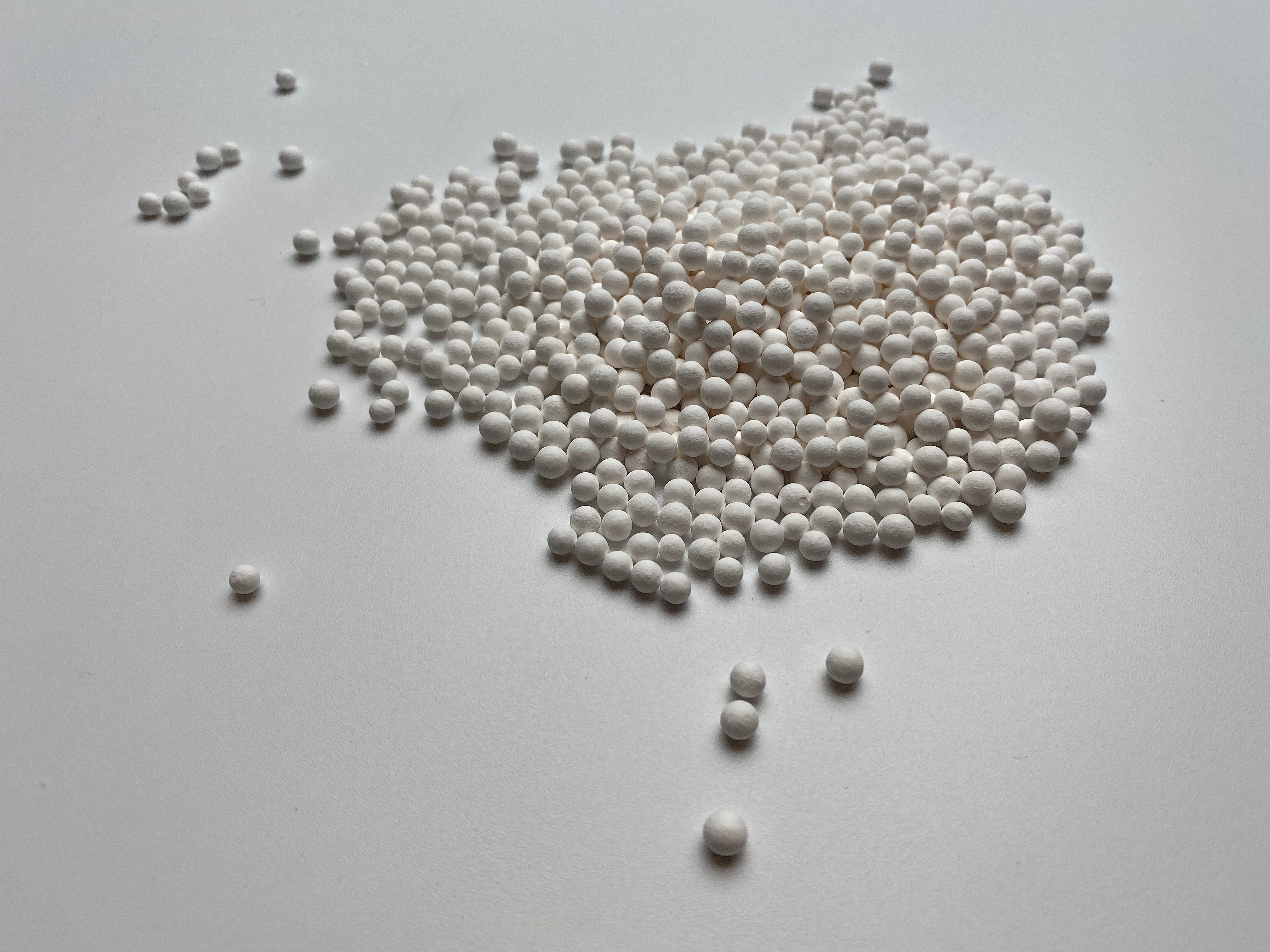

Activated alumina is a porous material with a high specific surface area. Its well-developed internal pore structure enables it to efficiently adsorb moisture from gases or liquids while maintaining its physical integrity. Its working principle relies on surface adsorption, capturing water molecules from the air to achieve deep drying of the airflow passing through the adsorbent layer. Compared with traditional desiccants such as silica gel, activated alumina spheres offer superior chemical stability—they are insoluble in acid and alkali solutions and do not soften or disintegrate upon direct contact with liquids. This makes them suitable for demanding industrial environments.

Its unique regenerability significantly reduces usage costs. By heating to 200–300°C, activated alumina can desorb the absorbed moisture, restoring its original adsorption capacity for repeated use. This feature not only reduces waste generation but also greatly lowers raw material procurement costs for businesses.

Overall, activated alumina has become an indispensable functional material in humidity control systems for the electronic components industry, thanks to its high moisture adsorption efficiency, corrosion resistance, high-temperature durability, and reusability.

Post time: Jun-16-2025