Dew point temperature is a critical indicator of gas dryness; under constant pressure conditions, the lower the dew point, the drier the gas. Since different industries have varying requirements for gas dryness, the selection of adsorbents for dryers must be optimized according to the specific application scenario.

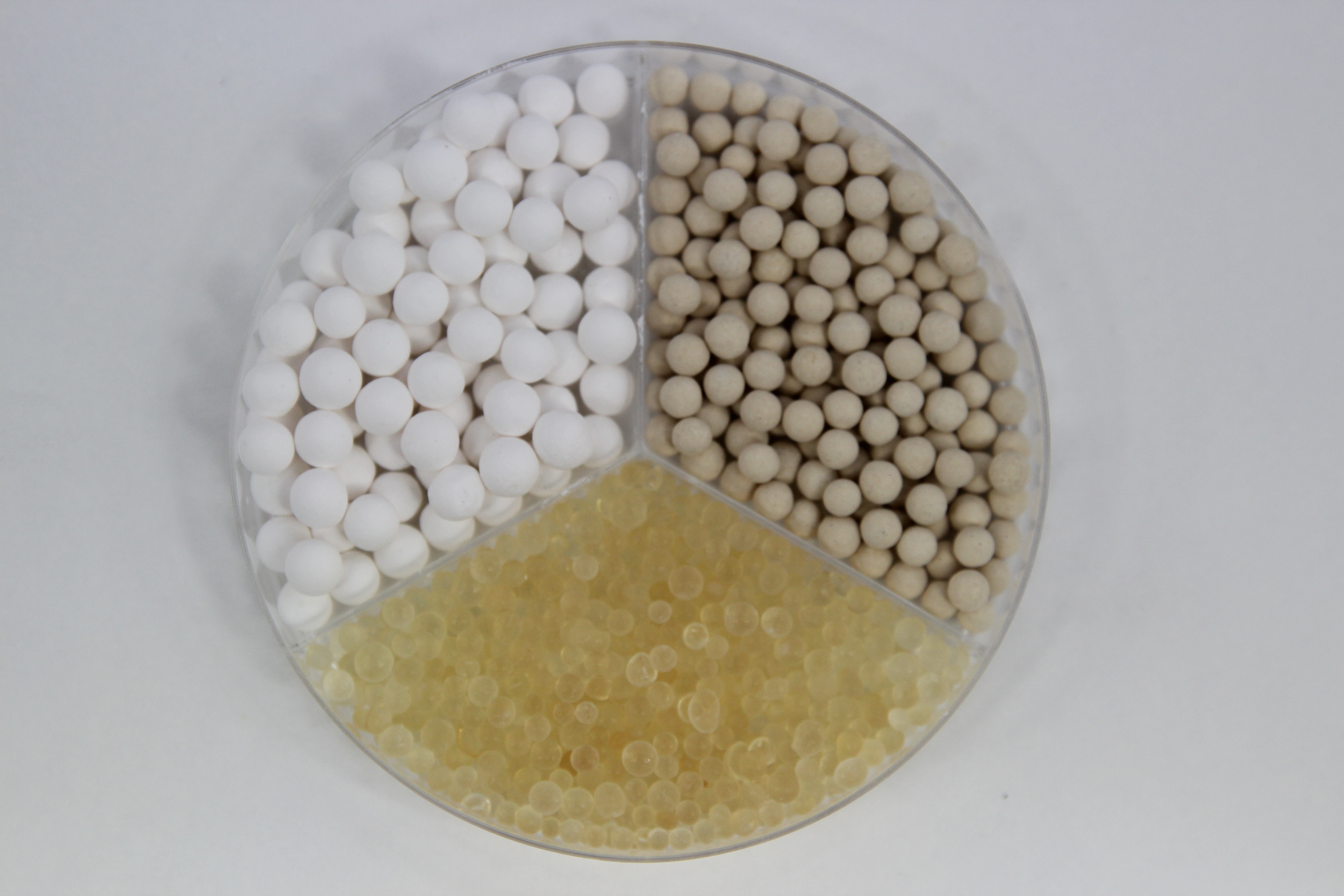

In basic industrial sectors such as compressed air systems, pneumatic tools, and injection molding machines, the drying requirements are relatively moderate. JOOZEO’s JZ-K1 activated alumina is a suitable choice as an adsorbent in these cases. This material features high mechanical strength and excellent crush resistance, making it ideal for variable operating conditions. Under optimal conditions, it can consistently achieve a dew point of -40°C. Its cost-effectiveness makes it well-suited for large-scale industrial applications.

For industries with extremely stringent gas dryness requirements—such as semiconductor manufacturing, electronic component production, and medical instrumentation—a composite adsorption approach is recommended. JOOZEO’s JZ-K2 activated alumina, with its high surface area, acts as a pre-adsorption layer to remove most of the moisture. This is followed by molecular sieves (such as type 13X), which provide deep dehydration to ensure the dew point drops below -70°C.

For special operating conditions—such as acidic environments or ultra-low dew point requirements—JOOZEO offers customized products including modified molecular sieves. Combined with dynamic adsorption simulation technology, these solutions optimize operating parameters to ensure long-term stability and high adsorption efficiency, delivering the most effective adsorbent solution.

Post time: May-13-2025