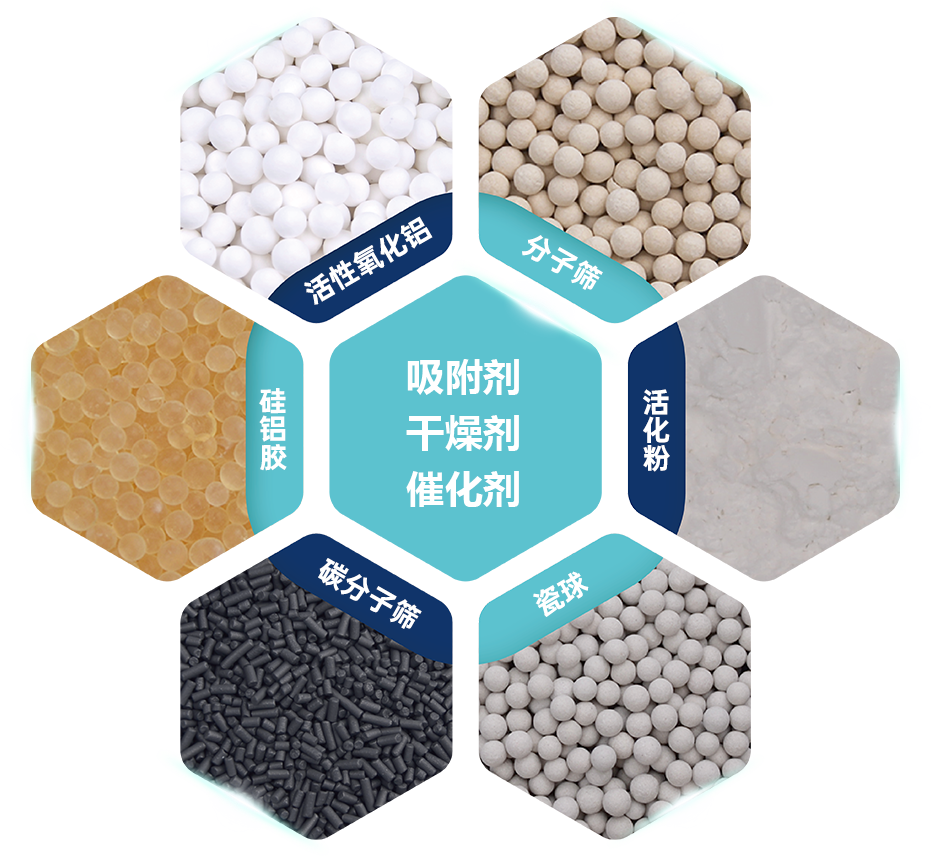

One of the core performance factors of an air dryer lies in the selection of adsorbents. While general-purpose adsorbents such as activated alumina, molecular sieve, and silica gel can meet basic needs, customized adsorbents are the ultimate solution for achieving high-efficiency, energy-saving, and environmentally friendly drying in various industries and processes.

When developing custom adsorbents, the following factors should be considered:

-

Gas Composition: The type, concentration, and temperature of the target gas must be analyzed to optimize the adsorbent material and ensure selective adsorption of water molecules or other impurities.

-

Drying Requirements: Depending on the target dew point, flow rate, and allowable pressure drop, the pore size, adsorption capacity, and kinetics of the adsorbent should be tailored to balance performance and energy consumption.

-

Operating Conditions: Pressure, temperature, humidity, corrosiveness, and dust levels must be taken into account. The adsorbent should be able to withstand complex conditions (e.g., high temperature, high humidity, oil-laden or corrosive gases) without performance loss or contamination.

-

Equipment Parameters: The adsorbent should be designed to match the air dryer model, tower dimensions, and regeneration method (heatless, heated, etc.), including considerations of particle strength, shape, and packing scheme.

JOOZEO is committed to providing high-quality custom adsorbents and services. From lab testing and operating condition simulation to mass production, we offer full technical support to ensure seamless integration between adsorbents and your equipment—helping businesses improve productivity, reduce costs, and achieve sustainable growth.

Post time: Apr-29-2025