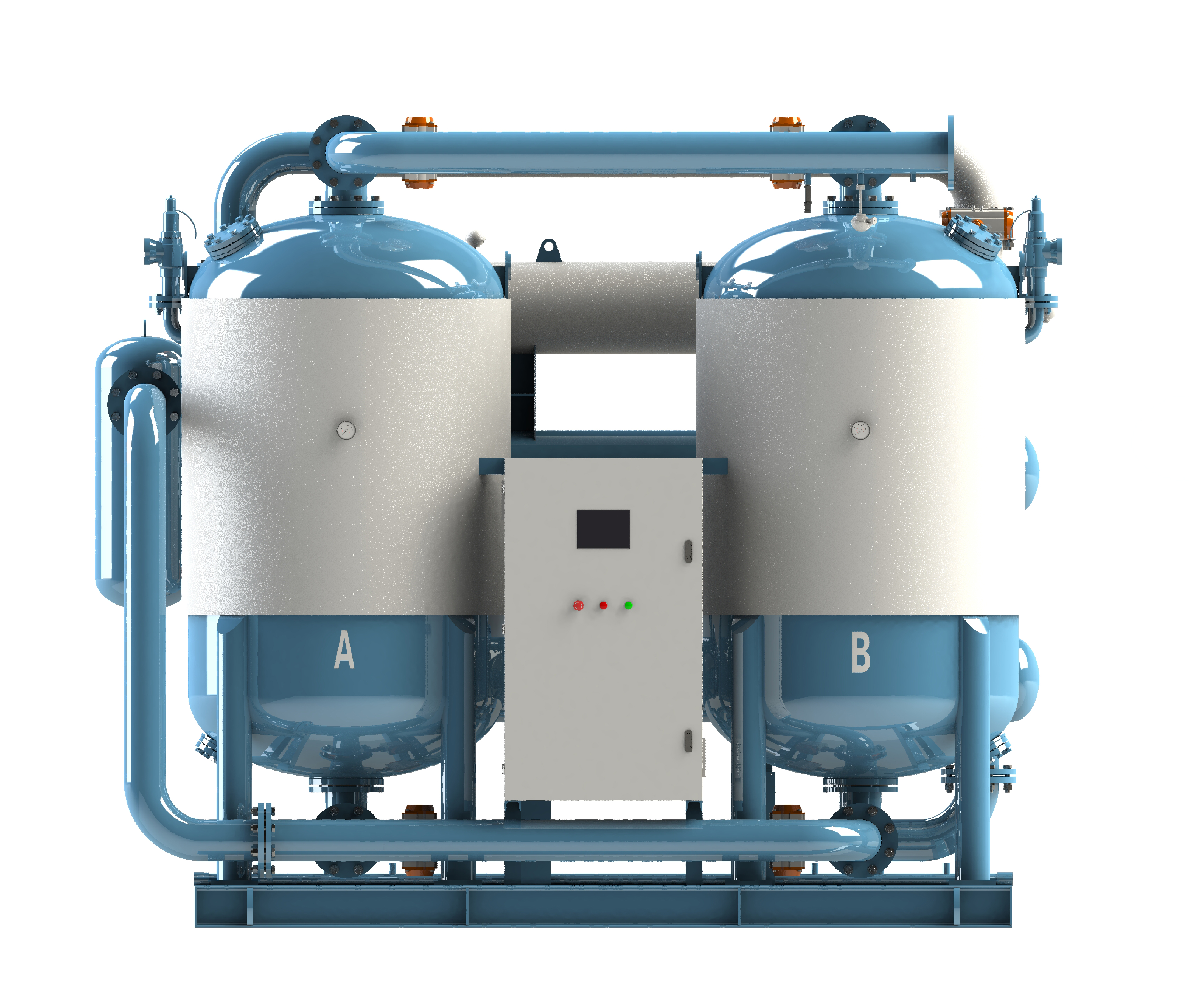

As a vital component in compressed air systems, desiccant dryers play a key role in ensuring air dryness and overall system efficiency. Regular replacement of adsorbents is essential for maintaining performance, and the process must follow standardized maintenance procedures, including the following steps and precautions:

First, ensure system safety. Completely depressurize the compressed air system after shutdown. Only after full pressure release should the filler and discharge ports on the dryer tower be removed. When discharging old adsorbents, use a thin rod to assist flow if blockage occurs, taking care to avoid contamination of equipment. It’s also recommended to remove and clean the coarse filters of the inlet and outlet pipelines simultaneously to ensure smooth airflow.

Filling new adsorbents is a critical step. Only use desiccants that meet specification requirements. Follow the desiccant loading chart to control filling height and use layered vibration filling techniques to ensure even compaction. Avoid using rods to forcefully press down, as this can crush the adsorbents. Eliminate any voids that could lead to air bypassing. A reasonable method is to place still-effective old adsorbents at the bottom of the vessel and fill new adsorbents in the upper section.

After replacement, carefully inspect all previously removed connections and conduct a system leak test. Upon restart, gradually adjust operating parameters and closely monitor initial performance to assess the effectiveness of the new adsorbents. Each maintenance operation should include detailed records of the replacement time, quantity used, and system performance to support future maintenance and optimization.

Throughout the entire replacement process, operational compliance and environmental cleanliness are essential. Ensuring proper adsorbent filling and system sealing is key to extending adsorbent life and maintaining optimal dryer performance.

Additionally, non-regenerable adsorbents should be properly disposed of in accordance with environmental regulations to avoid pollution.

Post time: May-26-2025