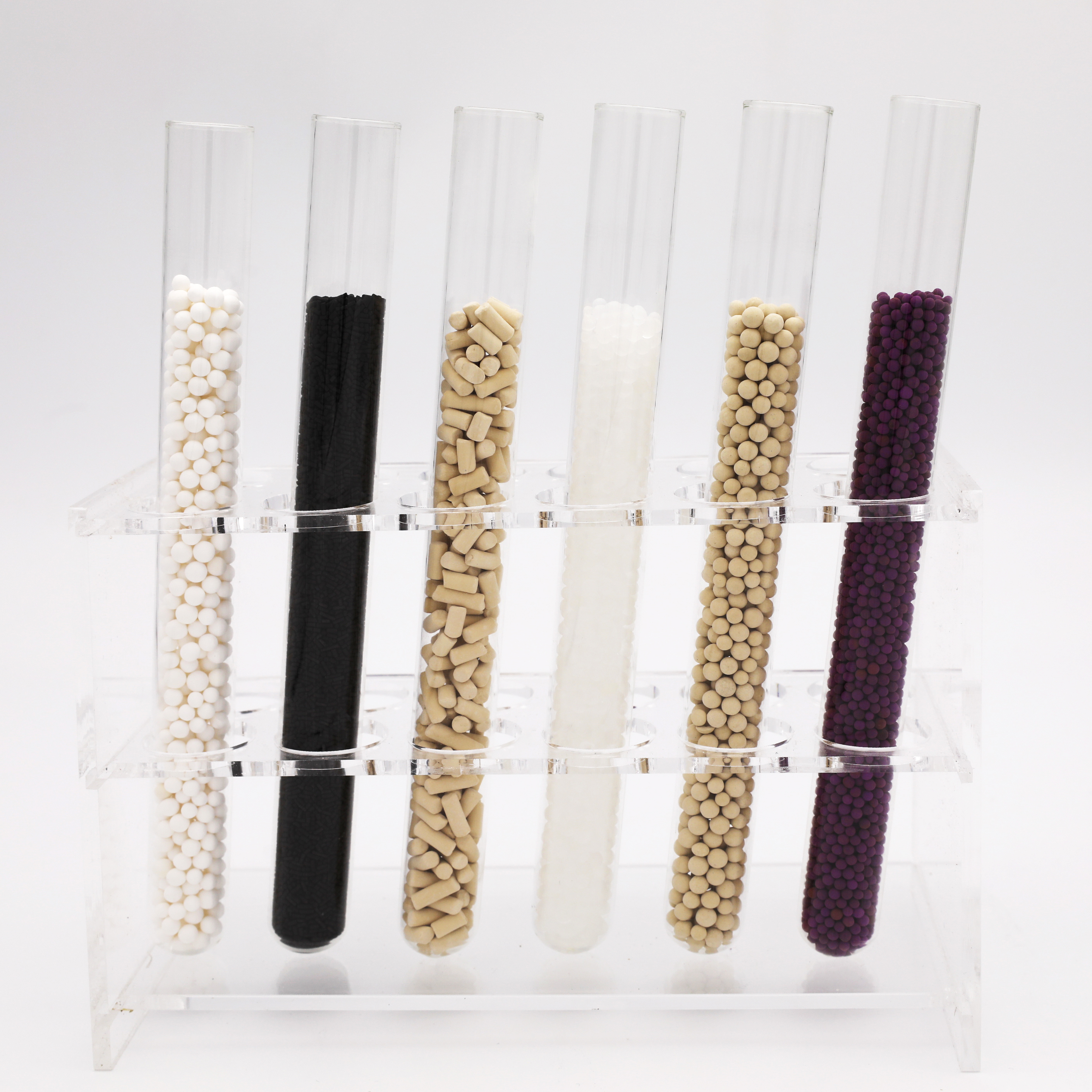

In compressed air drying systems, adsorbents such as activated alumina, molecular sieves, and silica-alumina gel are widely used due to their regenerative properties.

Regeneration—also known as desorption—is typically achieved using a heated regeneration method in air dryers. During operation, saturated adsorbents are heated and purged with dry air to remove moisture. Once regenerated, the adsorbents are cooled to operating temperature, restoring their adsorption capacity for repeated use.

Different types of adsorbents have different temperature requirements for regeneration. If the regeneration temperature is too low or the duration is insufficient, the process may be incomplete. This can reduce the compressive strength of the adsorbents, leading to powdering, negatively impacting equipment performance, lowering the quality of the final gas, and increasing maintenance costs.

With extensive industry experience, JOOZEO provides tailored adsorbent recommendations based on the specific type of air dryer (e.g., heatless, heated, or blower purge dryers). We also help optimize regeneration parameters—such as temperature, duration, and purge air volume—to ensure effective regeneration. This extends the adsorbent’s lifespan, ensures consistently high-quality dry air, and supports long-term stable operation of the equipment. JOOZEO is committed to delivering high-performance products, customized services, and energy-efficient, environmentally friendly adsorption solutions for our partners.

Post time: Apr-17-2025